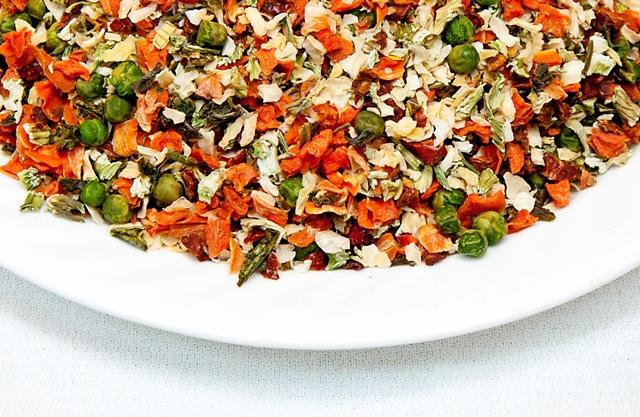

Freeze-dried foods have become a pantry staple for outdoor enthusiasts, emergency preppers, and health-conscious snackers alike—but have you ever wondered how that perfectly preserved strawberry or crunchy green bean gets made?

Freeze-drying, or lyophilization, is a sophisticated food preservation technique that removes moisture from fruits and vegetables while maintaining their shape, nutrients, and original flavor. Unlike traditional dehydration, which often shrinks and darkens produce, freeze-drying retains the vibrant appearance and structure of the original food. The result? Lightweight, shelf-stable products that rehydrate beautifully and maintain much of their nutritional value.

Here’s a closer look at the four precise stages of the freeze-drying process:

1. Pretreatment: Setting the Stage for Success

Before the actual drying begins, fruits and vegetables may undergo pretreatment steps designed to preserve color, enhance texture, or stabilize nutrients. Pretreatments vary depending on the food and may include:

-

Blanching (brief boiling followed by cooling)

-

Dipping in antioxidant solutions (like ascorbic acid)

-

Slicing or cutting for even drying

This phase ensures that the food is primed for optimal preservation in the next stages.

2. Freezing: Locking in Freshness

Freezing is the most critical step in freeze-drying. Here, the food is quickly brought to very low temperatures (well below 0°F), which preserves:

-

Cell structure

-

Color

-

Nutritional content

In small-batch production, items may be placed in glass flasks and cooled with dry ice and methanol or liquid nitrogen. Larger-scale operations rely on industrial freeze-dryers that rapidly freeze the food to a solid state, locking in all its characteristics.

3. Primary Drying (Sublimation Phase): Removing Ice

Next comes the primary drying phase, where approximately 95% of the water content is removed. This is done through a vacuum chamber where:

-

Pressure is lowered significantly

-

Controlled heat is applied

This causes the frozen water in the food to sublimate—that is, transform directly from a solid to a gas—without passing through a liquid stage. Because the food doesn’t melt, its shape and structure remain intact.

4. Secondary Drying: The Final Moisture Sweep

In the last step, the temperature is gently raised further to eliminate any remaining water molecules bound to the food on a molecular level. This step breaks potential chemical bonds and drives off "hidden" moisture that could reduce shelf life.

In some cases, a slight increase in air pressure is applied to help specific foods retain ideal texture. The result? Foods with as little as 1–4% moisture—perfect for long-term storage and easy rehydration.

Why Freeze-Dried Is a Smart Choice

Freeze-dried fruits and vegetables:

-

Retain up to 90–97% of their original nutrients

-

Are lightweight and easy to transport

-

Have shelf lives of 20+ years when properly stored

-

Rehydrate quickly with little texture loss

Whether you're building a food storage plan or just want healthy snacks with no added preservatives, freeze-dried foods are a modern marvel of preservation technology.

Stay tuned for our upcoming guide on how to safely store and rehydrate freeze-dried foods at home—including tips for maximizing flavor and nutrition.